-

files/JMR-Web_Slider.jpg

files/JMR-Web_Slider.jpg

-

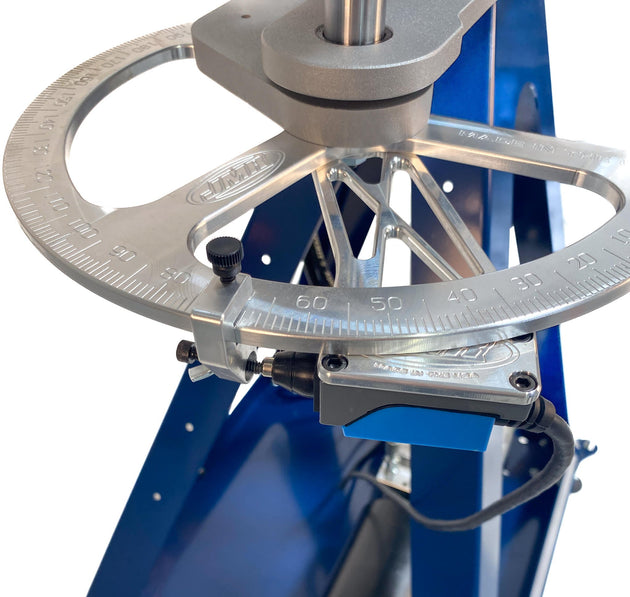

MADE IN USA

-

FAST SHIPPING

-

PRODUCTS IN STOCK

Let customers speak for us

from 19 reviewsFinally got around to mounting and setting up my notcher. It is a very well made notcher. I’m very happy with it and can’t wait to use it. The tolerances are so tight that I thought something was wrong with mine because I couldn’t hand turn it. Once I hooked a drill up, smooth as butter. I’m glad I went with JMR over the competitor that I was contemplating. Should serve me well for my aluminum welding business

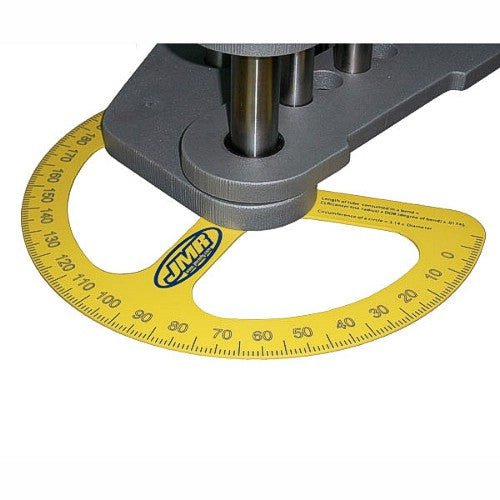

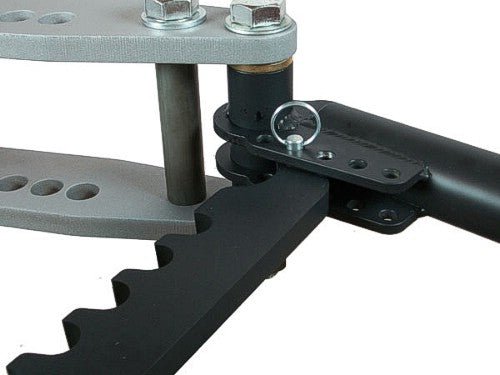

I did a lot of research when it came to buying a tube bender, ended up always coming back to this one. Out of the box ready to go, JMR always answered my questions even before I bought the bender. Fast, repeatable bends in a small well put together package. The auto stop is extremely easy to use, able to train operators easily. I am taking mine a little farther with adding my own indexing table, giving me the repeatability and quality of a bender easily 3x the price.

Great quality

Awesome dies thanks , and great customer service I will definitely be doing more business with them

Purchased my JMR tube bender back in 2007. This unit has performed flawlessly especially during production runs. I just purchased a 4” die for stainless tubing. The product shipped on Friday and I had it the next day. Just an absolutely great product.

This notcher works amazing and we use them in all of our field service trucks daily and have never been let down. Unlimited angles and the ability to clamp on an existing vertical pipe to install hinge pins makes it invaluable to us!!!! This is the little brother to the big dog (TN1000) See my review of that notcher everything I said about it is true of this one!!!!

I bought my first JMR notcher over 15 years ago and now have 4 in our commercial shop we even have the smaller ones in each of our field service trucks. This thing is built like a Swiss watch, The machine work looks like something out of a Formula 1 car or Aero space. Unlimited angles and the ability to clamp on an existing vertical pipe to install hinge pins make invaluable to us!!!! We have tried other notchers (regrettably) and there lack of rigidity tears up hole saws immediately. THERE IS NO BETTER NOTCHER PERIOD!!!!

I bought this bender over 15 years ago and use it in our full time commercial fabrication shop almost every day. It has made me more money per $ spent than ANY other tool I have bought in 20+ years in business. Beware of the copy cat fakes they are SHIT!!!! There is NO other company that has the fabrication knowledge that JMR does PERIOD!!!!

Thank you JMR for the quality product and customer service! I chose the 90 degree option and could not be more pleased.

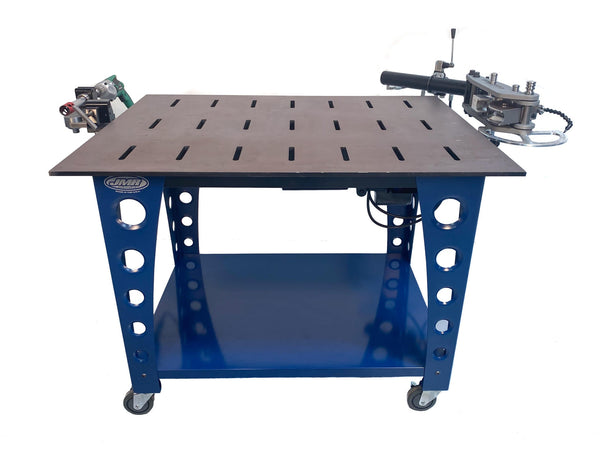

JMR Manufacturing is an American owned and operated company located in Paso Robles, California. JMR Manufacturing produces the highest quality fabrication tools for many different industries around the world. Have questions or looking to place a custom order? Please call (805)-239-5972 or email us at info@jmrmfg.com.